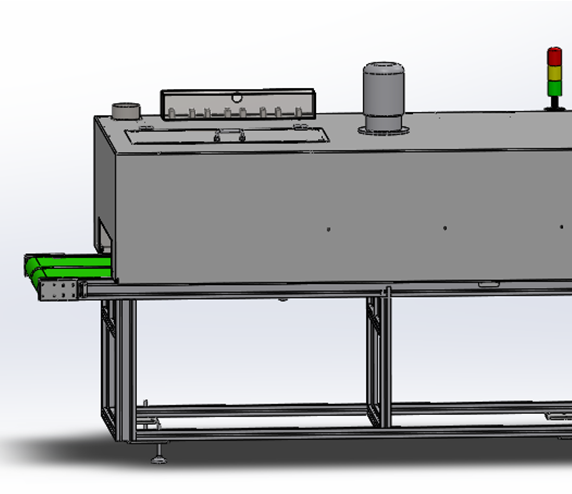

1, product name: Straight tunnel furnace

2, product model: HGC-600

3, Profile Size: L5600 * W1200 * H1650(mm)(estimated, depending on the actual machine size)

4, PLC + PID control, stable and reliable performance, temperature control and furnace temperature curve high precision

5, the use of Modular design, easy maintenance and quick, can reduce maintenance time and cost

6, with a variety of failures of sound and light alarm and information prompt function, including temperature deviation, speed deviation, Card Board, air transportation failure and wrong operation, etc. .

7, the adoption of a new gas management system, can make the furnace hot gas exchange efficiency is higher, to obtain better thermal compensation and thermal efficiency

8, concise control panel, centralized power switch, large cover switch, assembly line edge guard drop

9, heating area with independent Inverter, easy for customers to achieve different production process

10, PLC control, stable and reliable performance, high degree of repetition, the other key control components are imported brands, stable performance, durable and durable

11, furnace temperature 65 ° C +-5, effective constant temperature baking length 5m

12, Pu belt transmission, the overall operation curing time is 5-8min

13, heating area in the top can be opened and closed electrically, convenient tunnel maintenance and more heating Rod

14, conveyor speed adjustable 0-3m/Min.