LED lighting industry solutions

Date:2021-08-30 10:21:02Viewed:2908

China is a major producer and consumer of lighting products. According to estimates, China's electricity consumption for lighting accounts for about 12% of the total electricity consumption of the whole society. Based on the large population of China and the rapid development of the country's economy in recent years, the huge electricity consumption of lighting in the country has also brought thinking about energy shortages and environmental pollution. With the introduction of the national energy conservation and environmental protection policy, a "Roadmap to Eliminate Incandescent Lamps in China" declared that traditional incandescent lamps will inevitably withdraw from the stage of history. At the same time, the technology of LED lighting products is becoming more and more mature, and the luminous efficiency of LED chips continues to increase, reaching or even exceeding the level of energy-saving lamps, while the cost continues to decline. On the other hand, under the background of energy conservation and environmental protection and the government's vigorous publicity, the perceptions of consumers around the world are also changing. All of this is conducive to the popularization and promotion of LED lighting.

LED sapphire substrate has many advantages: firstly, the production technology of sapphire substrate is mature and the device quality is good; secondly, sapphire has good stability and can be used in high-temperature production process; finally, sapphire has high mechanical strength, is easy to handle and Clean.

The hardness of sapphire is very high, and its hardness is second only to diamond in natural materials, but it needs to be thinned and cut in the manufacturing process of LED devices, and its cutting accuracy is calculated at the μm level, which is for sapphire substrate cutting The craftsmanship puts forward very high requirements.

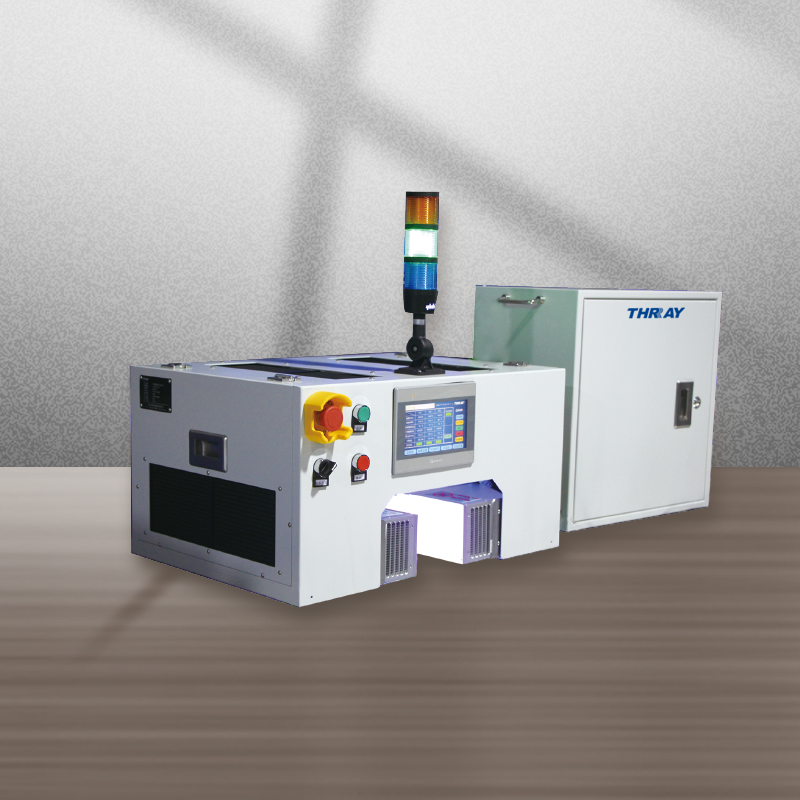

As an advanced processing technology, laser uses high-energy-density beams to precisely cut sapphire materials, which has significant advantages:

● Laser beam for non-contact processing, no consumables, while traditional diamond tool machining is easy to cause material waste, the tool is easy to wear, and needs to be replaced regularly.

● Small thermal influence, high processing accuracy, tens of thousands of chips can be cut on a two-inch wafer, and the chip spacing is only 0.02mm.

●It has a fully automatic loading and unloading system, which significantly reduces labor costs and improves production efficiency.